Construction

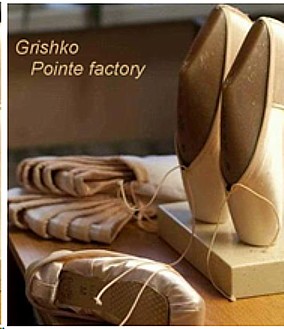

| GRISHKO POINTE SHOE CONSTRUCTION

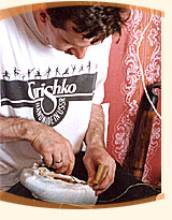

The difference between the technology of production of a GRISHKO pointe shoe and that of any other company is the fact that our shoes are truly, completely hand made. In GRISHKO factory we stitch the sole to the shoe by hand; this allows us to stitch through all the layers of box materials. This makes the box strong and the pointe shoes durable. Companies, which use mechanical stitching methods, cannot stitch through all the layers of box materials, because of the thickness of the box. After the sole has been stitched to the shoe GRISHKO masters start the process of hammering the pointe shoe box (working the shoe with a specialized hammer) which they repeat twice. In our factory this is all done manually. In the first stage the master spreads paste around the inside of the damp box, so as to prevent lumps forming and to be sure that all the layers are evenly glued.

That way the box has even thickness and is equally strong on all sides. If the customer prefers we can make the wings of the box thinner. After the sole has been stitched on and the pointe shoe turned inside out, the master hammers the shoe box again, leveling the whole area and polishing it on all sides. Special care is given to the platform – it is adjusted with mathematical precision down to the last millimeter. The edges of the platform which have to be accurately shaped, are balanced and smoothed to perfection. It is the upper and side borders that are vital for the stability of the pointe shoe.

A lot of manufacturers use specialized, mechanical presses for this procedure and only execute the last stage by hand. This does not allow the box to obtain the best form, because when pressed mechanically the paste can harden unevenly, the box can become lumpy and the edges of the platform may be uneven. At GRISHKO‘s the box is glued with natural and environmentally friendly paste, which has a dextrin-flour base. It becomes flexible on exposure to high temperature and humidity. When a ballerina starts dancing in these shoes, the heat from her feet makes the paste flexible and allows the box to mould itself to her foot. Other companies do not have such a potent and flexible paste, Another characteristic attribute of our pointe shoes, which cannot be obtained through mechanical production, is a well flattened sole, as our masters actually hammer the pointe shoe manually. When produced mechanically, the bottom is often a convex shape. GRISHKO pointe shoes are designed with highly qualified technologists working with researchers and scientists to ensure that pointe shoes are the best possible for your feet, your performance and your health. In summary, using these methods skilled GRISHKO craftsmen carefully create each and every shoe perfectly with attention to minute detail. This offers significant benefits over mechanical processes. As the great ANNA PAVLOVA said – A Pointe shoes made by her cobbler gave the shoe his heart and soul. Grishko Pointes made for the World Market are carefully quality control checked and signed by the cobbler. |